Call us:(86)13287951690

Brake drum parts: dust cover & shaft head

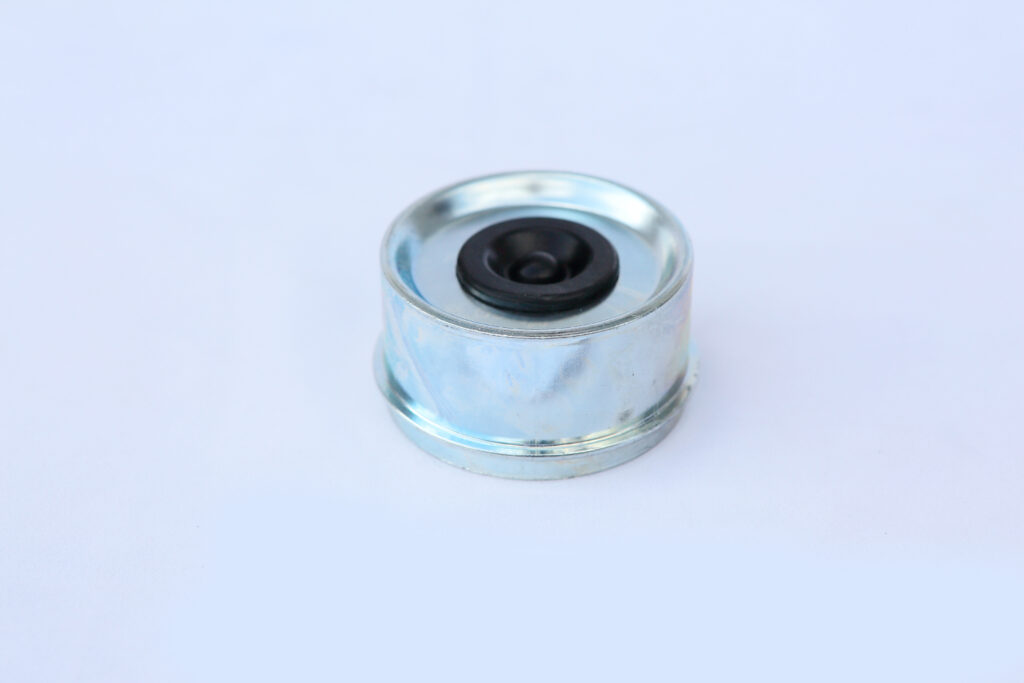

2. Dust Cover

The dust cover is a seemingly simple but crucial protective component.

Function and Purpose

Core Function: Prevents contaminants such as dust, sand, rainwater, and salt from entering the wheel hub bearing.

Maintaining Lubrication: Protects the grease in the bearing from contamination and loss, ensuring long-term proper operation and extending its service life.

Aesthetics: Enhances the wheel’s appearance and overall aesthetics. Many dust covers feature brand logos for identification purposes.

Common Materials

Stamped steel: The most common, low-cost, and strong material. The surface is typically electroplated (zinc, chrome) or painted to prevent rust.

Plastics (such as ABS and nylon): Lightweight, rust-resistant, offering greater styling freedom and competitive cost, making them increasingly popular.

Aluminum Alloy: Primarily used in high-end vehicles or the aftermarket, combining lightweight and aesthetically pleasing materials.

Manufacturing Process

Stamped steel: Cutting → Stamping → Trimming → Surface Treatment (Electroplating/Painting).

Plastic Parts: Injection Molding → Trimming the Sprues → (Electroplating/Painting).

Aluminum Alloy Parts: Stamping or Casting → Machining → Polishing/Painting.

Key Quality Points

Sealing: The fit with the axle or wheel hub must be tight, typically designed with a snap-fit or interference fit to prevent dislodging during vehicle vibration.

Rust/Weather Resistance: The surface treatment must withstand harsh environments and prevent rust and aging.

Dimensional Consistency: Ensure smooth installation and secure fit.

3. Axle Joint

The axle joint is a key load-bearing and transmission component that connects the braking system, wheel hub bearing, and wheel.

Function and Role

Mounting Base: It is the direct mounting component for the wheel hub bearing, brake drum/disc, and wheel.

Torque Transmission: For the drive wheels, the axle joint (or steering knuckle journal) is connected to the drive shaft via splines or bolts, transmitting engine power to the wheels.

Load-bearing capacity: Bears the vehicle’s vertical loads as well as the significant lateral and longitudinal forces generated during cornering and braking.

Common Materials: Medium carbon steel or alloy structural steel (e.g., 45#, 40Cr): Requires excellent strength and toughness and is typically forged.

High-strength cast iron: Used for some non-drive wheel axle ends.

Manufacturing Process: Forging is the core process to ensure mechanical properties.

Process Flow: Cutting → Heating → Forging → Normalizing/Quenching and Tempering Heat Treatment → Machining (Lathing, Milling, Drilling) → Grinding (Key Areas) → Cleaning/Rust Prevention.

Quality Key Points: Mechanical Properties: Strength, hardness, and toughness must be rigorously guaranteed through heat treatment.

Dimensional Accuracy: Extremely high dimensional tolerances, roundness, and surface finish are particularly important for the journal area where the bearing is mounted, directly impacting bearing life and smooth operation.

Geometric Tolerances: Concentricity and perpendicularity of the mounting surfaces are crucial.

No defects: Forgings must not have defects such as cracks and folds.